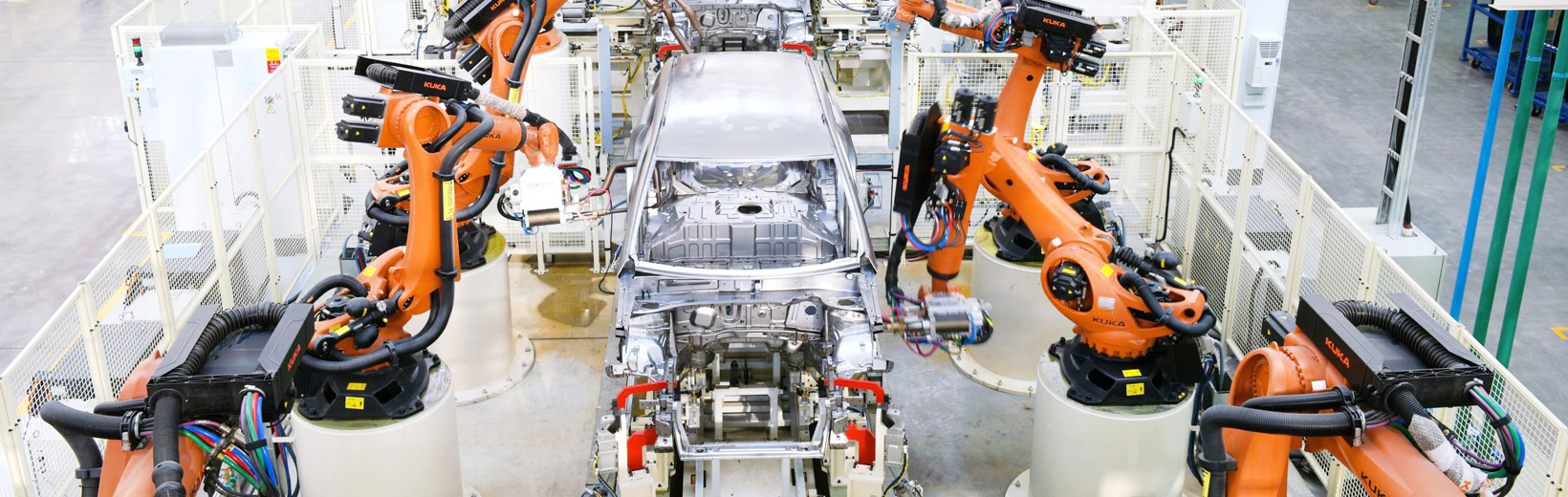

Auto Mobile

Jrss Steel offers multi-product portfolio of strip, tubes and forging steels, including a smart range of advanced products and a range of andvanced engineering services which support its customers to lower their total cost of ownership.

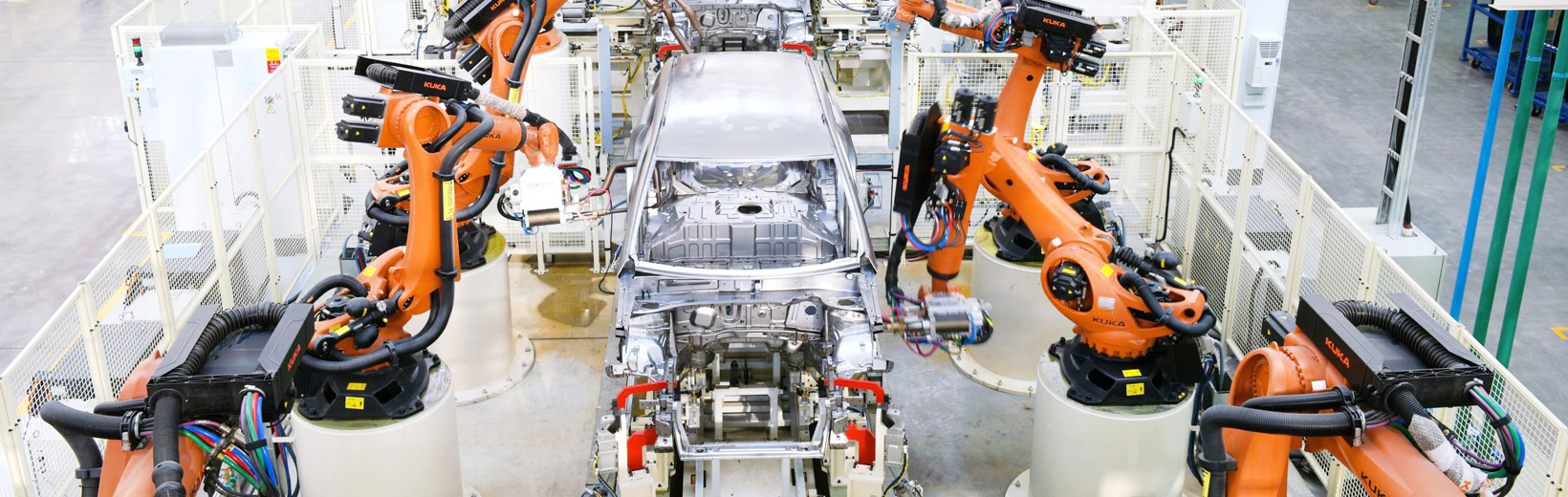

With higher elongation levels,more formable than their standard equivalents. The enhanced formability enables the design of more complex parts that are lighter and have better functionality and/or superior aesthetics.

This allows robust processing – with lower rejection rates, less downtime and improved press shop yield.

Our forming steels are available in a wide range of grades and corrosion resistant coatings.

Each grade is designed for specific applications and comes with a choice of surface quality. Extensive dimensional choice provides opportunities for cutting waste and maximising yield.

Our forming steels is a premium formable steel grade with very good deep drawing and stretching properties in all directions.This enables production of stylish outer panels with complex shapes, like sharp feature lines and extra deep sections.

Applications

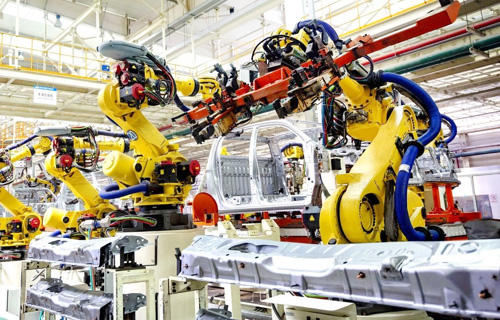

Our high-strength steels are used for both:

- wheel arches

- door inner parts

Our range of metallic coated high-strength steels includes micro alloyed, interstitial-free and bake hardening grades.

Our forming steels are used for complex shaped interior and exterior parts. These include:

Applications

high-strength steel grades, whose unique metallurgical properties and manufacturability enable the automotive industry to affordably meet increasingly stringent requirements. Ideal for applications requiring high strength and good formability. Due to their single-phase microstructures, properties are very consistent. This results in reliable production processes.

- interior (unexposed) parts

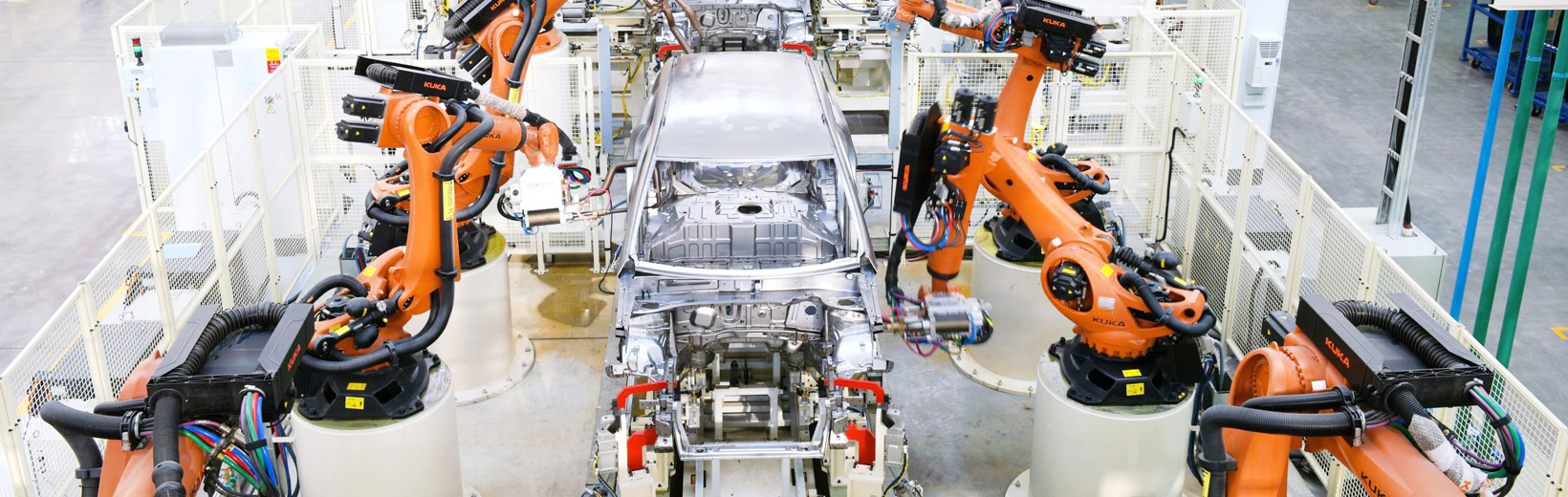

Steel Cars Offer a Great Environmental Advantage

Automobiles are the most recycled consumer product. Each year the steel industry recycles more than 14 million tons of steel from end-of-life vehicles. This is equivalent to nearly 8.5 million new automobiles. The steel recycling rate for automobiles is near--or above--100 percent annually. This recycling record, along with developing lighter, stronger steels continues to yield environmental benefits which are sustainable.

Even while these accomplishments are impressive, the steel industry continues to work to develop new, advanced steel products and applications that will yield even greater energy benefits to manufacturers and their customers. Advanced high-strength steels are strong, lighter, and produced with light life cycle impact, helping automakers decrease a vehicle’s life-long carbon footprint.

And because it is fully recyclable, steel used in today’s cars can help automakers reduce the carbon footprint of tomorrow’s vehicles, as well.

When one considers the total vehicle life cycle, steel is the most environmentally effective choice for automakers due to its relatively low energy and emissions during the manufacturing phase, significant mass reduction during the driving phase, and 100 percent recyclability at the end of the vehicle’s life. With continued steel and technology developments, greater efficiencies will be realized.

jacky@jrsspipe.com

jacky@jrsspipe.com

0086 135 8788 2121

0086 135 8788 2121

Mon - Sat 9.30 - 19.30

Mon - Sat 9.30 - 19.30